Chongqing Cummins Engine Co., Ltd. (CCEC) continues to elevate its Tier 4 non-road engines, presenting a new lineup at the Beijing International Construction Machinery Exhibition (BICES 2023) from September 20 to 23. The showcase includes Cummins’ commitment to zero-carbon with a multifuel engine platform, robust high-horsepower products, emission control systems, and advanced digital intelligence for core protection, filtration, and lubrication.

CCEC’ latest Tier 4 engines, incorporating nearly a hundred innovative technologies, build upon the durability and outstanding performance of the Tier 3 products. The engines exhibit significant increases in power and torque, ensuring enhanced adaptability for operations under demanding conditions.

Extensive real-world testing, totaling millions of operational hours, has surpassed the expectations of OEMs and end-users. The most significant change in Cummins Tier 4 engines is the introduction of a two-dimensional system, ensuring fuel economy.

Users of excavators equipped with Cummins Tier 4 engines report:

Exceptional performance in heavy-duty operations (50 to 65-ton range), with ample power reserves. Operational efficiency increases by 10% in conditions such as earthmoving, mining, and loading, showcasing suitability for high-altitude operations up to 3000 meters without torque limitations.

Strong crushing impact, fast material processing, and remarkable fuel efficiency. Field tests indicate a potential fuel saving of around 15% for similar tasks within the same time frame.

CCEC has accumulated over 5.9 million hours of runtime with its in-use Tier 4 products, with the longest single-machine runtime exceeding 8,000 hours and an online network of over 30,000 units, reflecting impressive growth.

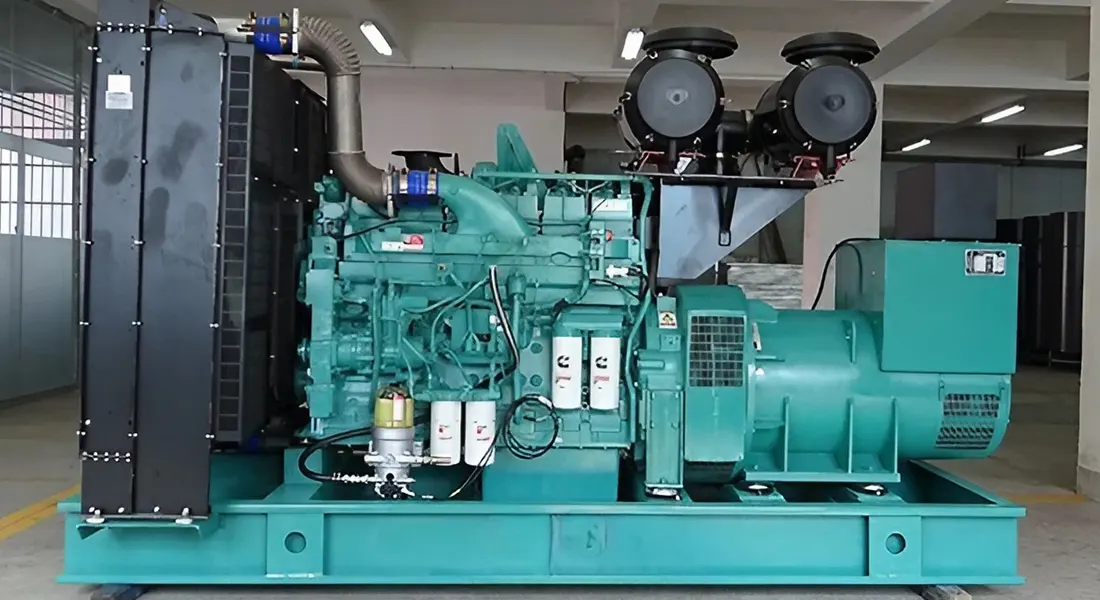

The Tier 4 non-road engine lineup from Cummins comprises F2.8, B3.9, B5.9, F4.5, B7/B6.7, L9, X12, and 15-liter series, covering a power range of 36 to 503 kW. This broad application spectrum spans excavators, loaders, drills, cranes, dozers, graders, pavers, milling machines, rollers, and compressors.

The holistic design and technological details of the core components underwent systematic optimization. This includes the adoption of a more responsive electronic control module, a lower fuel consumption high-pressure common rail fuel system, and a more efficient aftertreatment system, resulting in better integration with the entire machine. In addition to high reliability and economy, Cummins Tier 4 products feature advanced digital and intelligent capabilities, providing long-lasting usage while achieving energy efficiency and environmental protection.

CCEC’ Tier 4 emission solutions follow two main technical routes: one for small to medium-sized engines (3.9L, 4.5L, and 5.9L) utilizing EGR+DOC+DPF technology and another for larger horsepower segments in medium to heavy-duty platforms (6.7L and above) utilizing DOC+DPF+SCR technology. The EGR route eliminates the need for urea injection and requires minimal adjustments to the overall machine framework, simplifying the transition to Tier 4. The efficient SCR route demands higher conversion efficiency with increasing engine horsepower, achieved by Cummins’ advanced emission treatment system with integrated design, space savings, lower fuel consumption, higher integration, and adaptability with the entire machine.

CCEC introduces the PLUS high-end custom Tier 4 products — F4.5 PLUS, L9 PLUS, and M15 PLUS — featuring core optimization and robust power. With forward-looking integration into whole machine equipment and high system integration, these products exhibit strong adaptability in engineering applications, delivering exceptional performance in fuel savings, efficiency improvement, consumption reduction, and emission reduction for higher profitability.

CCEC’ emission treatment system for non-road Tier 4 equipment offers professional customized products, including diesel oxidation catalyst (DOC), diesel particulate filter (DPF), selective catalytic reduction (SCR), and urea injection system (UL2.2). Tailored to market demand, these products provide multiple arrangement options for flexible installation, covering various engineering equipment categories such as excavators, loaders, cranes, drills, dozers, harvesters, and more. With advanced purification technology, efficient ash cleaning for carbon soot, intelligent fuel identification for enhanced reliability, and easy remote calibration system upgrades significantly reduce maintenance downtime.

Furthermore, CCEC’ large horsepower engines, known for their strength, reliability, and high availability, have gained widespread acclaim among construction machinery and mining customers. Encompassing displacements from 14L to 50L, the QSN, QSK19, QSK38, and QSK50 series offer power ranges from 235 to 2500 horsepower (175 to 1864 kW). The showcased QSK38 high-horsepower intelligent electronic control engine, with power ranging from 1200 to 1600 horsepower (896 to 1193 kW), utilizes a high-pressure common rail fuel system suitable for markets such as construction machinery, mining, pumps, oil and gas fields, marine and rail.

For the first time, CCEC’ multifuel engine platform makes its debut in China at the BICES 2023, aligning with the zero-carbon strategy and meeting next-stage emission design requirements. With the majority of common components, this platform can use various types of fuels, including a range of clean diesel, natural gas, hydrogen, propane, and other low-carbon or zero-carbon fuels. With high power density, compact structure, convenient installation, and usage, this platform not only ensures operational cost advantages but also boosts productivity.

STAY IN THE LOOP

Subscribe to our free newsletter.

An export trade deal for a 520KW diesel generator set bound for Malaysia.

The UL 1247 certification issuance ceremony for china’s first electronically controlled firefighting diesel engine and the WTDP witness testing accreditation laboratory awarding ceremony successfully held.

Chongqing Cummins has played a pivotal role in meeting the diverse demands.