On November 20, Chongqing Cummins’ high-power technology center successfully ignited its engine test bench, marking a pivotal milestone in the future development of Chongqing Cummins. Members of the Chongqing Cummins board and staff from the technology center witnessed this historic moment.

Spanning 400 acres, the future development project includes Chongqing Cummins’ high-power technology (R&D) center, high-power engine production line, Cummins Power Business Unit Chongqing Technical Center, office building, training center, and related supporting facilities. This initiative positions Chongqing Cummins to become one of Cummins’ most critical global hubs for high-power engine manufacturing and R&D, catering to both domestic and international markets, with an annual production capacity of 22,000 high-power engines.

Cao Side, Cummins Vice President Global, delivered a speech at the ceremony, emphasizing the importance of the “market-oriented” strategy as a driving force for Cummins’ continued progress. He highlighted the necessity of robust local R&D capabilities to meet market demands. The birth of the High-Power Technology Center in Chongqing will channel more resources and capabilities to develop products tailored to user needs in China. It signifies a new driving force for Chongqing Cummins’ development and a vital link in Cummins’ global R&D chain.

Ms. Chen Ping, General Manager of Chongqing Machinery & Electric Co., Ltd., and Chairman of Chongqing Cummins, expressed confidence in Chongqing Cummins’ future development. She pledged continued support from Chongqing Machinery & Electric and encouraged Chongqing Cummins to persist in the successful launch of high-power projects, ensuring the scientific, safe, and efficient completion of the project’s second phase.

The current Phase I construction houses Chongqing Cummins’ high-power technology (R&D) center, the only high-power engine R&D center of Cummins in China. It possesses advanced capabilities for researching and testing Cummins’ latest high-power diesel and gas engines. The center plans six engine test benches, equipped with state-of-the-art dynamometers capable of generating up to 3500 kilowatts. These facilities enable performance testing, emission testing, and reliability testing for engines ranging from 14L to 72L displacement. The electrical energy generated during testing meets the power demands of all equipment in the technology center. The testing equipment at the center is supplied by AVL, an Austrian company specializing in engine test equipment. The emission testing capabilities comply with the requirements of U.S. Tier 4 Final and China’s Non-Road Stage V emission regulations. The exhaust gases from engine testing, after treatment by exhaust after-treatment equipment, meet the latest national environmental regulations. The R&D and testing management at the technology center adhere to Cummins standards, ensuring a unified global level of R&D and testing quality and providing users in China and globally with Cummins’ high-standard R&D and testing services.

STAY IN THE LOOP

Subscribe to our free newsletter.

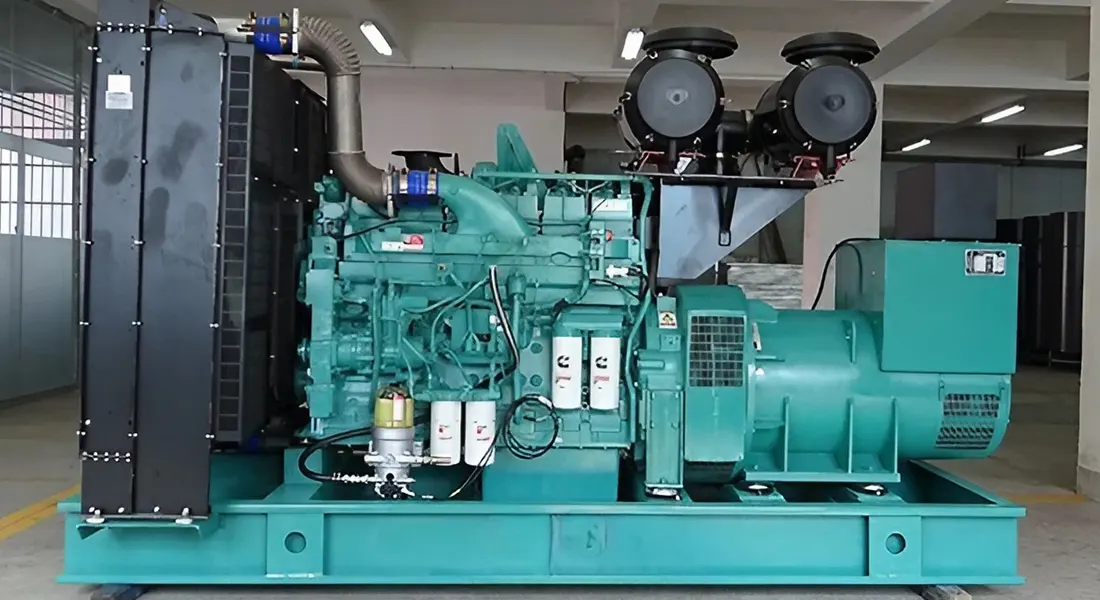

An export trade deal for a 520KW diesel generator set bound for Malaysia.

Cummins continues to elevate its Tier 4 non-road engines.

The UL 1247 certification issuance ceremony for china’s first electronically controlled firefighting diesel engine and the WTDP witness testing accreditation laboratory awarding ceremony successfully held.