Chongqing Cummins Engine Co., Ltd.’s new facility officially commenced operations on November 18, 2022. As Cummins’ first engine joint venture in China, Chongqing Cummins has played a pivotal role in meeting the diverse demands of the Chinese high-horsepower market. The establishment of the new facility marks a breakthrough in both advanced manufacturing and research and development in the high-horsepower sector.

Situated in the Liangjiang New Area of Chongqing, the new Chongqing Cummins facility spans an impressive 400 acres (equivalent to 38 standard football fields). Built to Cummins’ global advanced standards, the facility boasts industry-leading equipment and software, integrating an Innovation Technology Center, advanced manufacturing systems, and an efficient logistics system.

The state-of-the-art High-Horsepower Technology Center is Cummins’ exclusive institution in China dedicated to high-horsepower engine technology research and development. With a core focus on the R&D testing of high-horsepower engines, the center possesses capabilities for mechanical performance testing, emission testing, durability testing for engine assemblies and components, as well as new product installation and existing product modifications. The emission equipment on test benches meets the stringent requirements of non-road Stage IV emission regulations in China and T4F non-road Stage IV emission regulations in the United States. The benches are also equipped with cutting-edge alternating current power dynamometers with a maximum power of 3000 kW, converting consumed fuel during testing into electricity for factory use, aiding in reducing the factory’s carbon footprint

The Chongqing Cummins new facility comprises two assembly lines and a centralized assembly line for the assembly of 19-liter, 38-liter, and 50-liter engines. All production lines are digitally, intelligently, and automatically integrated, constructed in accordance with Cummins’ high-horsepower engine production line standards. After more than a year of trial operation, the production lines have comprehensively achieved established goals in safety, capacity, quality, and other key indicators. The new facility includes nine testing rooms that cover testing for diesel and natural gas engines ranging from 11 to 72 liters, equipped with advanced hardware and control systems, making it the most advanced testing bench within Cummins’ global network.

The logistics system at the new facility is meticulously planned based on international logistics industry standards. Combining the logistics system of the original production base with the new factory’s capacity and the latest market demands, the system’s logic has been improved and upgraded to optimize storage, distribution, and warehouse management. This ensures the timely delivery of the correct quantity of qualified components to the correct production line station at the right time. The factory utilizes advanced automated guided vehicles for material distribution, reducing the labor intensity of production line workers, significantly improving distribution efficiency, and ensuring both safety and reliability with enhanced intelligence.

STAY IN THE LOOP

Subscribe to our free newsletter.

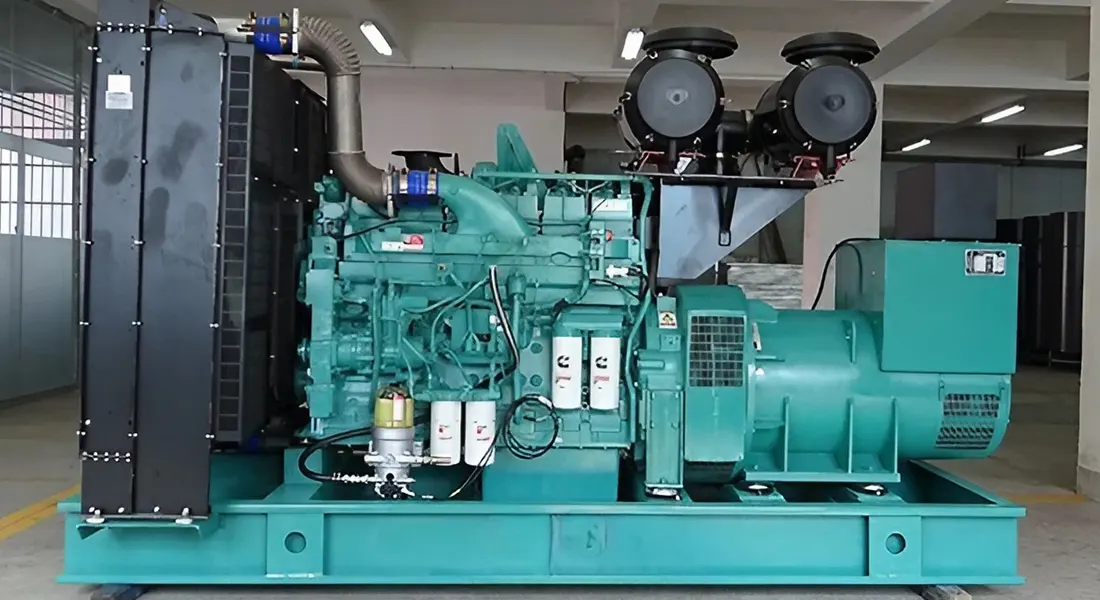

An export trade deal for a 520KW diesel generator set bound for Malaysia.

Cummins continues to elevate its Tier 4 non-road engines.

The UL 1247 certification issuance ceremony for china’s first electronically controlled firefighting diesel engine and the WTDP witness testing accreditation laboratory awarding ceremony successfully held.