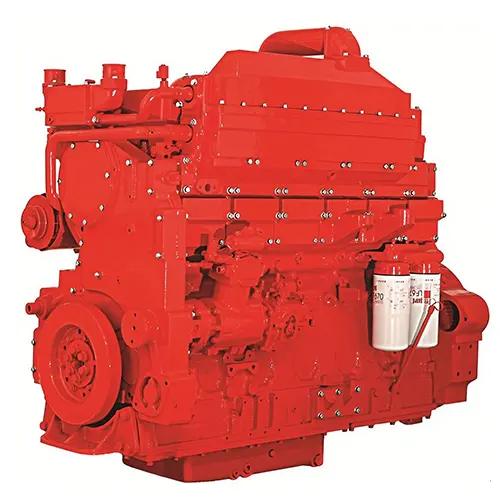

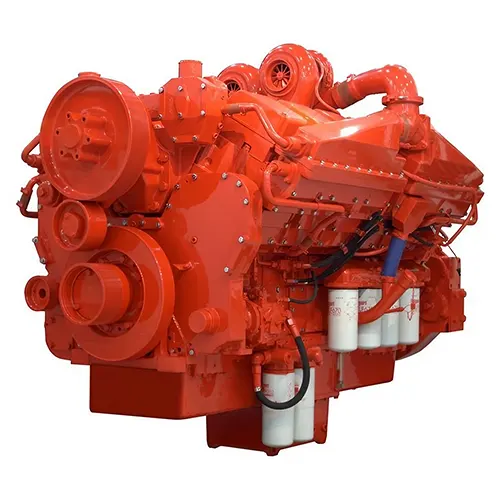

| Engine Model: | KTA50-P1915 |

| Engine Type: | 4 Cycle, 60° Vee, 16 Cylinder Diesel |

| Displacement: | 3067 in³ / 50.3 L |

| Rated Speed: | 1800 RPM |

| Rated Power / Speed: | 1429 kW @ 1800 RPM |

| Aspiration Method: | Turbocharged & Water-Air Intercooler |

| Emission Standard: | N/A |

| Bore*Stroke: | 6.25 in * 6.25 in / 159 mm * 159 mm |

| Packing Size(L*W*H): | 2857 mm * 1415 mm * 1766 mm |

| Wet Weight: | 12485 lb / 5662 kg |

| Lead Time: | 15-30 Working Days |

| Payment Terms: | T/T, L/C |

Introduction

Chongqing Cummins Engine Co., Ltd. (CCEC) KTA50-P1915(1500 RPM) Pump Drive Engine is V type 16-cylinder, 50.3 liters four-strokes engine with 159 mm (6.25 in) bore and 159 mm (6.25 in) stroke.

KTA50-P1915 Pump Drive Engine equipped with PT Fuel System, comes with turbocharger and Low Temperature Aftercooled. The Maximum power at 1500 RPM of CCEC KTA50-P1915 pump drive engine is 1915 HP (1429 kW), The prime power at 1500 RPM of CCEC KTA50-P1915 pump drive engine is 1608 HP (1200 kW). The maximum torque of the engine at 1800 RPM is 5544 N.m.

For extensive years, Neoengery has been a steadfast collaborator with CCEC, emerging as an expert pump system solution provider with vast experience. Catering to a global clientele, we deliver comprehensive one-stop pump system solutions – from design and supply to seamless installation, efficient commissioning, and ongoing after-sales support. As your dependable pump system partner, Neoengery ensures optimal value for your investment, offering reliable system solutions with a focus on customer satisfaction.

Advantages of KTA50-P1915 Pump Engine

- High-Quality Components for Efficiency and Durability – Benefit from superior engine performance with high-quality alloy cast iron, offering enhanced rigidity, reduced vibration, and noise. Wet and replaceable cylinder liners improve heat rejection and facilitate easy replacement, ensuring optimal engine function.

- Precision Engineering for Fuel Efficiency and Reliability – Experience optimized fuel consumption and emission performance with 4 valves per cylinder and a meticulously designed engine structure. Quality alloy cast iron, a single cylinder head, a dedicated camshaft, and a robust outline contribute to improved reliability and durability.

- Innovative Fuel Injection for Enhanced Performance – Explore precise fuel injection with CMS unique PT and Step Timing control, achieving a pressure above 120Mpa. This results in outstanding fuel efficiency and emission performance, further enhanced by a check valve in the fuel tube for increased reliability.

- Efficient Cooling and Clean Coolant – Ensure efficient cooling through a gear water pump and well-designed flux channels. The spin-in water filter maintains coolant cleanliness, preserving normal acidity levels and contributing to prolonged engine life.

- Advanced Turbocharging for Optimal Results – Experience advanced Holset turbocharging and after-cooled technology, complemented by a pulse exhaust manifold for reduced exhaust temperature. This combination ensures excellent fuel consumption and emission performance, delivering an optimized engine experience.

| Engine Model: | Max. Rating | Aspiration | Curve & Datasheet | Compression Ratio | Fuel System |

| KTA50-P1645 | 1227 kW (1645 HP) @ 1800 RPM | Turbocharged & Water-Air Intercooler | FR-6250 | 13.9 : 1 | CMI PT |

| KTA50-P1915 | 1429 kW (1915 HP) @ 1800 RPM | Turbocharged & Water-Air Intercooler | FR-6243 (1 P / 2 L) FR-6351 (2 P / 2 L) |

14.9 : 1 | CMI PT |

| KTA50-P2220 | 1657 kW (2220 HP) @ 1800 RPM | Turbocharged & Water-Air Intercooler | FR-6259 | 13.9 : 1 | CMI PT |

| KTTA50-2000 | 1491 kW (2000 HP) @ 1900 RPM | Dual turbocharger and Low Temperature Aftercooled | FR-6356 | 13.8 : 1 | CMI PT |

| General Infomation of CCEC KTA50-P1915 Pump Engine | |

| Engine Model | KTA50-P1915 |

| Maxi. Rating | 1429 kW (1915 HP) @ 1800 RPM |

| Curve & Datasheet | FR-6243 (1 P / 2 L); FR-6351 (2 P / 2 L) |

| Compression Ratio | 14.9 : 1 |

| Type | 4 Cycle, 60° Vee, 16 Cylinder Diesel |

| Fuel System | CMI PT |

| Aspiration | Turbocharged & Water-Air Intercooler |

| Packing Size (L * W * H) | 2857 mm * 1415 mm * 1766 mm |

| Configuration | D283022DX02 |

| CPL Code Revision | 2354 (1 P / 2 L); 2859 (2 P / 2 L) |

| Fan to Flywheel | 3170289 (1 P / 2 L) / 3626419 (2 P / 2 L) |

| Displacement | 3067 in³ / 50.3 L |

| Bore * Stroke | 6.25 in * 6.25 in / 159 mm * 159 mm |

| Dry Weight (Fan to Flywheel Engine) | 11820 lb / 5360 kg |

| Dry Weight (Heat Exchanger Cooled Engine) | N/A |

| Wet Weight (Fan to Flywheel Engine) | 12485 lb / 5662 kg |

| Wet Weight (Heat Exchanger Cooled Engine) | N/A |

| C.G. Distance From Rear Face of Flywheel Housing (FH 6024) | 47.5 in / 1206 mm |

| C.G. Distance Above Crank Centerline | 11.0 in / 279 mm |

| Maximum Static Loading at Rear Main Bearing | 2000 lb / 908 kg |

| Maximum Bending Moment at Rear Face of Block | 4500 lb.ft / 6100 N.m |

| Moment of Inertia of Rotating Components (Excluding Flywheel) – With FW 6009 Flywheel | 301 lbm.ft2 / 12.7 kg.m2 |

| Moment of Inertia of Rotating Components (Excluding Flywheel) – With FW 6017 Flywheel | 515 lbm.ft2 / 21.7 kg.m2 |

| Barometric Pressure | 100 kPa / 29.53 in Hg |

| Altitude | 110 m / 361 ft |

| Steady State Stability Band at any Constant Load | ± 0.25 % |

| Air Temperature | 25 °C / 77 °F |

| Relative Humidity | 30% |

| Maximum Allowable Power From Accessory Drive | N/A |

| Estimated Free Field Sound Pressure Level of a Typical Generator Set — Excludes Exhaust Noise; at Rated Load and 7.5 m (24.6 ft) – 1500 RPM | 92.4 dBA |

| Estimated Free Field Sound Pressure Level of a Typical Generator Set – Exhaust Noise at 1 m Horizontally from Centerline of Exhaust Pipe Outlet Upwards at 45° | N/A |

| Scopes of Supply of CCEC KTA50-P1915 Pump Engine | |

| Fuel System | Fuel Transfer Pump |

| High-Pressure Fuel Pump | |

| Fuel Filter | |

| Exhaust System | Exhaust Manifold |

| Turbocharger | |

| Exhaust Elbow | |

| Air Intake System | Air Intake Manifold |

| Water-air Intercooler | |

| Air Filter | |

| Starting System | Starter Motor |

| Starter Rely | |

| Cooling System | Water Pump |

| Engine Fan | |

| Standard Radiator | |

| Power Output System | Flywheel |

| Standard Flywheel Housing | |

| Lubricating System | Oil Pump |

| Oil Filter | |

| Charging System | Charging Alternator |

| Engine Shut-Down System | Engine Fuel Shut-Off Solenoid |

| Engine Mounting System | Engine Mounting Bracket |

| Control System | Various Engine Speed Controller |

| Optional Accessories of CCEC KTA50-P1915 Pump Engine | |

| Air Intake System | Air Intake Pre-Heater |

| Air Intake Pre-filter | |

| Air Filter Alarm System | |

| Exhaust System | Muffler & Bellows |

| Flame Trap | |

| Spark Arrestor Type Muffler & Bellows | |

| Dpf System | |

| Fuel System | Coarse Filter |

| Fuel Pre-Heater | |

| Lubricating System | Oil Pre-Heater |

| Starting System | Manual Magnetic Dc Contactor |

| Dual Ears Flywheel Housing | |

| Spring Starter Motor | |

| Air Starter Motor | |

| Hydraulic Starter Motor | |

| Cooling System | Coolant Pre-heater |

| Jacket Water Heater | |

| Engine Auxiliary Accessories | Hydraulic Oil Pump |

| Hydraulic Clutch | |

| Control System | Engine Monitor |

| Engine Protection System with Alarm System | |

| Mechanical Engine Control Lever System | |

| Electric Engine Control Lever System | |

| Power Output System | Gear Reduction Gearbox |

| Reverse Gear Box | |

| Engine Mounting System | Shock Absorber Pad |

| Modifiable Components of CCEC KTA50-P1915 Pump Engine | |

| Air Intake System | Installation Position of Air Filter |

| Upgrade to Heavy-Duty Type Air Filter | |

| Charging System | 12V Charging Alternator for 12v Electric System |

| Explosion-Proof Charging Alternator | |

| Upgrading to Specified Brand and Specifications of Charging Alternator | |

| Exhaust System | Water-Cooled Exhaust Manifold |

| Water-Cooled Turbocharger | |

| Modify Option for Installation Position and Direction of Turbocharger | |

| Lubricating System | Oil Pan Position |

| Number of Dipstick | |

| Position of Dipstick Can Choose from 6 Positions | |

| Modify Option for Oil Filter to be Remote Installation | |

| Engine Shut-Down System | 12V Solenoid for 12V Electric System |

| Explosion-Proof Solenoid | |

| Starting System | Upgrading to Specified Brand and Specifications of Starter Motor |

| 12V Starter Motor for 12V Electric System | |

| Fuel System | Upgrade to Fuel Filter that Integrated with Fuel Transfer Pump and Fuel Pre-Heater |

| Engine Auxiliary Accessories | Additional Auxiliary Systems can be Added for Special Applications |

| Cooling System | Modify Option for Engine Fan into Keel Cooling System |

| Power Output System | Modify Option for Size of Flywheel Housing and Flywheel |

| Dual-Ear Flywheel Housing (For Twin-Starter System) | |

| Some of Models can Modify Flywheel Housing Into PTO Integrated Type | |

| Engine Have Connecting Port of PTOs, That Able to Provide Power Output | |

| Engine Mounting System | Modify Option for Engine Mounting Bracket |

***Note: All Above Data are Just for Reference, All Data Might Change Without Notices or Updates, Please Contact Our Sales Team to Confirm All Details Via WhatsApp or Email.