| Engine Model: | K38N-G6 |

| Engine Type: | 4 Cycle, 60° Vee, 12 Cylinder |

| Displacement: | 38 L |

| Rated Speed: | 1500 RPM |

| Rated Power / Speed: | 660 kW @ 1500 RPM |

| Aspiration Method: | Turbocharged & Water-Air Intercooler |

| Emission Standard: | N/A |

| Bore*Stroke: | 159 mm * 159 mm |

| Packing Size(L*W*H): | N/A |

| Wet Weight: | 4100 kg |

| Lead Time: | 15-30 Working Days |

| Payment Terms: | T/T, L/C |

Introduction

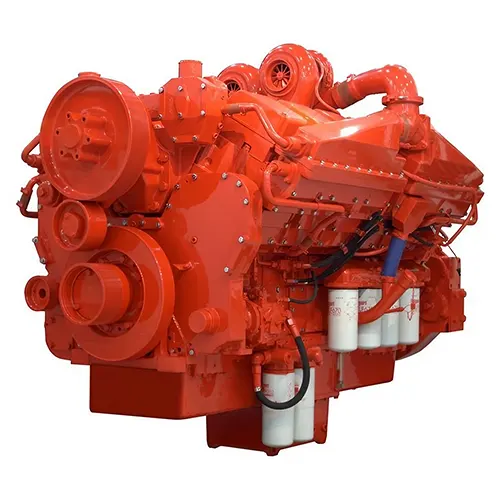

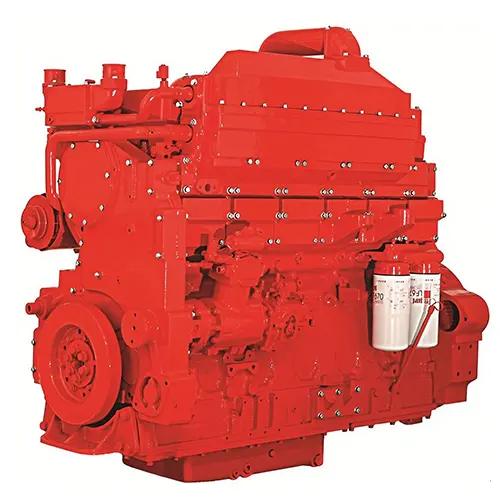

Chongqing Cummins Engine Co., Ltd. (CCEC) K38N-G6(1500 RPM) Gas Generator Drive Engine is 12-Cylinder Inline, 38 liters Four-Strokes Engine with 159 mm (6.25 in) Bore and 159 mm (6.25 in) Stroke.

K38N-G6 Gas Generator Drive Engine Equipped with Natural Gas Fuel System, Comes with Turbocharged & Water-Air Intercooler.The Standby Power for 50 Hz Generator Set (1500 RPM) of CCEC K38N-G6 Gas Generator Drive Engine is 885 HP (660 kW). The Prime Power for 50 Hz Generator Set (1500 RPM). The Continuous Power for 50 Hz Generator Set (1500 RPM) .

Neoenergy, underpinned by CCEC, delivers holistic power supply solutions to cater to diverse needs. Our product lineup includes Open Type Generator Sets, Silence Type Generator Sets, Super Silence Type Generator Sets, Mobile Trailers, Complete Power Trucks, and purpose-built Complete Power Cars, specially designed for railway applications. Explore a range that marries innovation with reliability.

Embark on a seamless journey with Neoenergy, where our commitment extends beyond products to comprehensive life cycle services. From the initial design phase to power system supply, installation, commissioning, after-sales service training, spare parts supply, troubleshooting, and complete overhaul technical support – Neoenergy is your enduring partner throughout the entire life cycle of your power infrastructure.

Advantages of K38N-G6 Gas Generator Drive Engine

- Engineering Excellence – Fortifying Power for Harsh Environments – At Neoenergy, our commitment to excellence is evident in our advanced design and sophisticated manufacturing processes. Crafted to endure various harsh working conditions, our engines feature high-strength parts with an inherent ability to withstand heavy loads, ensuring unwavering performance in challenging environments.

- Integrated Design for Enhanced Reliability – The integration of the cylinder block and cylinder head is a hallmark of Neoenergy’s commitment to preventing engine water and oil leakage. This integrated design not only ensures the prevention of leaks but also results in approximately 40% fewer parts compared to similar engines, significantly reducing failure rates and simplifying maintenance.

- Forged Steel Precision – Elevating Strength and Durability – Neoenergy’s engines are precision-engineered with forged steel camshafts and crankshafts. The high-strength cylinder block design, coupled with multiple parts cast on the cylinder block, provides exceptional rigidity, high pressure resistance, and an extended service life. Experience power solutions built for reliability and endurance.

- Innovative Cylinder Bore Design – Maximizing Efficiency – Neoenergy’s engines feature a platform mesh honing design in the cylinder bore, ensuring a perfect geometric structure that effectively prevents oil leakage. Advanced technologies, such as new piston ring components and gasket crimping and molding, further contribute to reducing oil loss, delivering optimal efficiency.

- Electronically Controlled Excellence – The five key systems of Neoenergy’s electronically controlled engines are meticulously developed by DCEC. Applied and verified globally in diverse fields, these systems ensure unparalleled economy and reliability. Neoenergy’s commitment to excellence shines through, providing a product that stands at the forefront of innovation and performance.

| Engine Model: | Prime Power | Aspiration | Configuration | Compression Ratio | Performance Curve |

| K38N-G5 | 560 kW ( 751 HP ) @ 1500 RPM | Turbocharged & Water-Air Intercooler | D813004GX03 | 11.5 : 1 | TBD |

| K38N-G6 | 660 kW ( 885 HP ) @ 1500RPM | Turbocharged & Water-Air Intercooler | D813004GX03 | 11.5 : 1 | TBD |

| K38N-G7 | 768 kW ( 1030 HP ) @ 1500 RPM | Turbocharged & Water-Air Intercooler | D813004GX03 | 11.5 : 1 | TBD |

| K38N-G8 | 900 kW ( 1027 HP ) @ 1500 RPM | Turbocharged & Water-Air Intercooler | D813004GX03 | 11.5 : 1 | TBD |

| General Infomation of CCEC K38N-G6 Gas Generator Drive Engine | |

| Engine Model | K38N-G6 |

| Curve Number | TBD |

| Configuration | D813004GX03 |

| Displacement | 38 L |

| Aspiration | Turbocharged & Water-Air Intercooler |

| Rating | 660 kW ( 885 HP ) @ 1500 RPM |

| Bore * Stroke | 159 mm * 159 mm |

| Fuel System | Natural Gas |

| Compression Ratio | 11.5 : 1 |

| Type | 4 Cycle, 60° Vee, 12 Cylinder |

| Wet Weight | 4100 kg |

| Moment of Inertia of Rotating Components without Flywheel | 10.4 |

| C.G. Distance From Rear Face of Block | 801 mm |

| C.G. Distance Above Crankshaft Centerline | 0 |

| Maximum Allowable Static Load at Rear Main Bearing | N/A |

| Scopes of Supply of CCEC K38N-G6 Gas Generator Drive Engine | |

| Fuel System | Fuel Transfer Pump |

| High-Pressure Fuel Pump | |

| Fuel Filter | |

| Exhaust System | Exhaust Manifold |

| Turbocharger | |

| Exhaust Elbow | |

| Air Intake System | Air Intake Manifold |

| Water-air Intercooler | |

| Standard Air Filter | |

| Starting System | Starter Motor |

| Starter Rely | |

| Cooling System | Water Pump |

| Engine Fan | |

| Standard Radiator | |

| Power Output System | Flywheel |

| Standard Flywheel Housing | |

| Lubricating System | Oil Pump |

| Oil Filter | |

| Charging System | Charging Alternator |

| Engine Shut-Down System | Engine Fuel Shut-Off Solenoid |

| Optional Accessories of CCEC K38N-G6 Gas Generator Drive Engine | |

| Air Intake System | Air Intake Pre-Heater |

| Air Intake Shut-Off Valve | |

| Heavy-Duty Air Filter | |

| Plateau Type Air Filter | |

| Exhaust System | Muffler & Bellows |

| Spark Arrestor Type Muffler & Bellows | |

| Dpf System | |

| Fuel System | Coarse Filter |

| Fuel Pre-Heater | |

| Lubricating System | Oil Pre-Heater |

| Starting System | Manual Magnetic Dc Contactor |

| Dual Ears Flywheel Housing | |

| Spring Starter Motor | |

| Air Starter Motor | |

| Hydraulic Starter Motor | |

| Cooling System | Silent Type Radiator |

| Plateau Radiator | |

| Salt-Spray Resistant Radiator | |

| Coolant Pre-Heater | |

| Jacket Water Heater | |

| Modifiable Components of CCEC K38N-G6 Gas Generator Drive Engine | |

| Air Intake System | Installation Position of Air Filter |

| Upgrade to Heavy-Duty Type Air Filter | |

| Charging System | 12V Charging Alternator for 12v Electric System |

| Explosion-Proof Charging Alternator | |

| Exhaust System | Water-Cooled Exhaust Manifold |

| Water-Cooled Turbocharger | |

| Modify Option for Installation Position and Direction of Turbocharger | |

| Lubricating System | Oil Pan Position |

| Number of Dipstick | |

| Position of Dipstick | |

| Engine Shut-Down System | 12V Solenoid for 12V Electric System |

| Explosion-Proof Solenoid | |

| Starting System | 12V Starter Motor for 12V Electric System |

| Fuel System | Upgrade to Fuel Filter that Integrated with Fuel Transfer Pump |

| Power Output System | Modify Option for Size of Flywheel Housing and Flywheel |

| Dual-Ear Flywheel Housing (For Twin-Starter System) | |

***Note: All Above Data are Just for Reference, All Data Might Change Without Notices or Updates, Please Contact Our Sales Team to Confirm All Details Via WhatsApp or Email.