| Engine Model: | QSK19-C700A |

| Engine Type: | 4 Cycle, In-line, 6 Cylinder |

| Displacement: | 19.0 L |

| Rated Speed: | 2000 RPM |

| Rated Power / Speed: | 555 kW @ 2000 RPM |

| Aspiration Method: | Turbocharged & Air-Air Intercooler |

| Emission Standard: | U.S. EPA Tier 3 |

| Bore*Stroke: | 158.75 mm * 158.75 mm |

| Packing Size(L*W*H): | 2857 mm * 1415 mm * 1766 mm |

| Weight, Net Dry: | 2072 kg |

| Lead Time: | 15-30 Working Days |

| Payment Terms: | T/T, L/C |

Introduction

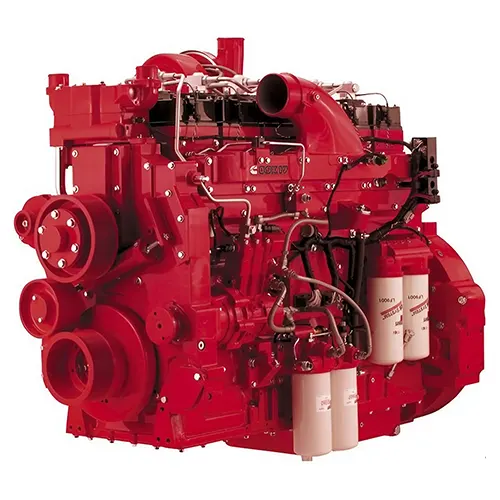

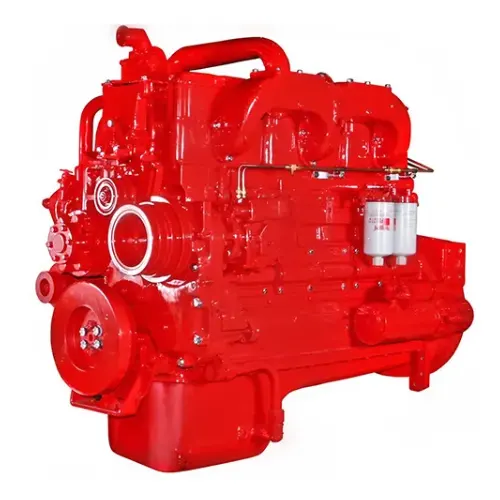

Chongqing Cummins Engine Co., Ltd. (CCEC) QSK19-C700A (2000 RPM) Industrial Engine is a 6-cylinder inline, 19 liters four-strokes engine with 159 mm (6.25 in) bore and 159 mm (6.25 in) stroke.

QSK19-C700A Industrial Engine equipped with CCEC Modular Common Rail Fuel System, comes with turbocharger and Air-Air intercooler, with a EURO III post-processor. The Advertised power at 2000 RPM of CCEC QSK19-C700A Industrial Engine is 700 HP (522 kW), The maximum torque of the engine at 1500 RPM is 2983 N.m.

Power Pack Solutions – Experience seamless industrial power with our integrated solutions. Our power packs include air intake, exhaust, cooling system, control system, transmission, and hydraulic accessories. Specialized offerings feature explosion-proof engines, generators, water pump sets, and ultra-low temperature condition engine power packs.

Comprehensive Life Cycle Services – We offer end-to-end services for our customers. From initial design to power system supply, installation to commissioning, after-sales service training to spare parts supply, and troubleshooting to overhaul technical support. Trust us for a comprehensive and reliable power solution throughout the entire life cycle of your system.

Advantages of QSK19-C700A Industrial Engine

- Enhanced Engine Performance – Achieve lower oil consumption and an extended stroke for more comprehensive combustion gas expansion, resulting in increased effective efficiency output and improved overall economy.

- Powerful Performance and Efficiency – Experience robust power with an advanced 4-air-valve structure, delivering greater horsepower. Thorough air burning enhances low-speed torque, accelerates response speed, and ensures vigorous climbing capabilities.

- Unmatched Reliability – With compulsive cold-cut articulated pistons, our engines withstand extreme mechanical and heat loads, offering strength comparable to heavy engines and ensuring excellent reliability.

- Optimized Emissions and Homogeneous Combustion – Improve emissions with a decorated injector and symmetrical combustion chamber, creating a more homogeneous mixture for thorough burning and reduced emissions.

- Extended Engine Life – Enjoy a superlative engine life, with 30% of engines reaching 800,000 km without overhaul, showcasing exceptional durability and longevity.

- Excellence in Lean-Burn Control – Benefit from excellent power and clean burning through an advanced lean-burn closed-loop electronic control system.

- Exceptional Cold Start Performance – Equipped with an air suction electric preheater and a 7.8 kW power starter, our engines exhibit outstanding cold start performance. Validated through extreme low-temperature tests, including the arctic village of MoHe in China at -36°C.

| Engine Model: | Rated Power | Aspiration | Curve & Datasheet | Compression Ratio | Fuel System |

| QSK19-C800 | 597 kW @ 2100 RPM | Turbocharged Charge-Air-Cooled | FR-4551 | 15.0 : 1 | CMI MCRS |

| QSK19-G3 | 608 kW @ 1800 RPM | Turbocharged and Air to Air Aftercooled | FR-4446 | 15.0 : 1 | CMI MCRS |

| QSK19-C760 | 567 kW @ 2100 RPM | Turbocharged Charge-Air-Cooled | FR-4549 | 15.0 : 1 | CMI MCRS |

| QSK19-C506 | 377 kW @ 1800 RPM | Turbocharged & Air-Air Intercooler | FR-4550 | 15.8 : 1 | MCRS |

| QSK19-C525 | 391 kW @ 2000 RPM | Turbocharged & Air-Air Intercooler | FR-4566 | 15.8 : 1 | N/A |

| QSK19-C560A | 418 kW @ 2000 RPM | Turbocharged & Air-Air Intercooler | FR-4522 | 15.8 : 1 | MCRS |

| QSK19-C560B | 418 kW @ 2000 RPM | Turbocharged & Air-Air Intercooler | FR-4567 | 15.8 : 1 | N/A |

| QSK19-C600 | 447 kW @ 2000 RPM | Turbocharged & Air-Air Intercooler | FR-4565 | 15.8 : 1 | N/A |

| QSK19-C675 | 503 kW @ 1800 RPM | Turbocharged & Air-Air Intercooler | FR-4510 | 15.8 : 1 | N/A |

| QSK19-C700A | 522 kW @ 2000 RPM | Turbocharged & Air-Air Intercooler | FR-4556 | 15.8 : 1 | MCRS |

| QSK19-C700B | 522 kW @ 1800 RPM | Turbocharged & Air-Air Intercooler | FR-4564 | 16 : 1 | MCRS |

| General Infomation of CCEC QSK19-C700A Industrial Engine | |

| Engine Model | QSK19-C700A |

| Maxi. Rating | 522 kW @ 2000 RPM |

| Curve & Datasheet | FR-4556 |

| Compression Ratio | 15.8 : 1 |

| Type | 4 Cycle, In-line, 6 Cylinder |

| Fuel System | MCRS |

| Aspiration | Turbocharged & Air-Air Intercooler |

| Packing Size(L*W*H) | 2857 mm * 1415 mm * 1766 mm |

| Configuration | D193101CX03 |

| CPL Code Revision | 3240 |

| Firing Order | N/A |

| Governed Power | N/A |

| Emission Standard | U.S. EPA Tier 3 |

| Peak Torque | 2983 N·m @ 1500 RPM |

| Displacement | 19.0 L |

| Bore*Stroke | 158.75 mm × 158.75 mm |

| Minimum Low Idle Speed | 600 RPM |

| Maximum Low Idle Speed | 1200 RPM |

| Engine Sound Pressure Levels3 (Noise) – Top Side | 96.6 dBA |

| Engine Sound Pressure Levels3 (Noise) – Right Side | 102.2 dBA |

| Engine Sound Pressure Levels3 (Noise) – Left Side | 100.0 dBA |

| Engine Sound Pressure Levels3 (Noise) – Right Side | 102.1 dBA |

| Engine Sound Pressure Levels3 (Noise) – Exhaust Noise with Aftertreatment | 122.2 dBA |

| Approximate Engine Weight (Wet)⁴ | 4569 lbm / 2072 kg |

| Maximum Overspeed Capability | 2400 RPM |

| Maximum Installed Engine Power Angle | 6 ° |

| Maximum Installed Engine Tilt Angle | 6 ° |

| MAss Moment of Inertia of Rotating Components (Excluding Flywheel) | 16.07 in-lbf-sec² / 1.82 kg-m2 |

| Approximate Engine Weight (dry)⁴Approximate Engine Weight (dry)⁴ | N/A |

| Moment of Inertia — X-Axis (Roll) | 1447 in-lbf-sec² / 163.4 kg-m2 |

| Moment of Inertia — Y-Axis (Pitch) | 3844 in-lbf-sec² / 434.3 kg-m2 |

| Moment of Inertia — Z-Axis (Yaw) | 3041 in-lbf-sec² / 343.6 kg-m2 |

| Center of Gravity — From Rear Face of Block | 23.55 in / 598 mm |

| Maximum Crankshaft Thrust Bearing Load Limit — Intermittent Load | 1500 lbf / 6672 N |

| Maximum Bending Moment Available From Front of Crankshaft — 270 Degrees | 440 lb-ft / 597 N.m |

| Maximum Static Bending Moment at Rear Face of Block | 2730 lb-ft / 3702 N.m |

| Maximum Crankshaft Thrust Bearing Load Limit — Continuous Load | 750 lbf / 3336 N |

| Center of Gravity — From Engine Centerline to Left Side of Engine (as Viewed From Rear of Engine) | N/A |

| Maximum Bending Moment Available From Front of Crankshaft — 0 Degrees | 440 lb-ft / 597 N.m |

| Maximum Bending Moment Available From Front of Crankshaft — 90 Degrees | 440 lb-ft / 597 N.m |

| Maximum Bending Moment Available From Front of Crankshaft — 180 Degrees | 440 lb-ft / 597 N.m |

| Center of Gravity — Above Crankshaft Centerline | 11.10 in / 282 mm |

| HTC Coolant Volume (Engine Only) | 44 quarts / 42 L |

| Maximum External HTC Restriction | 5 PSI / 34.5 kPa |

| HTC Thermostat Opening Temperature | 180 °F / 82 °C |

| Maximum Auxiliary Coolant Flow at 1800 Rpm | N/A |

| Maximum HTC Thermostat Outlet Temperature at Lat (Maximum Top Tank Temperature) | 212 °F / 100 °C |

| Minimum Operating HTC Temperature (For Continuous Cold Weather Applications) | 160 °F / 71 °C |

| HTC Thermostat Fully Open Temperature | 202 °F / 94 °C |

| Engine Performance Data CCEC QSK19-C700A Industrial Engine | ||||

| Advertised Power | Peak Torque | |||

| Engine Speed (RPM) | 1,800 | 1,500 | ||

| Power Output (HP / kW) | 700 | 522 | 629 | 469 |

| Torque Output (lb-ft / N.m) | 1,838 | 2,492 | 2,200 | 2,983 |

| Friction Horsepower (HP / kW) | 95 | 71 | 57 | 43 |

| Intake Manifold Pressure (in-Hg / kPa) | 68 | 230 | 63 | 213 |

| Turbo Comp. Outlet Pressure (in-Hg / kPa) | 72 | 243 | 66 | 223 |

| Turbo Comp. Outlet Temperature (°F / ℃) | 392 | 200 | 375 | 191 |

| Inlet Air Flow (ft>3/min / L/s) | 1,900 | 897 | 1,450 | 684 |

| Charge Air Flow (lb/min / kg/min) | 136 | 62 | 103 | 47 |

| Exhaust Gas Flow (ft>3/min / L/s) | 4,430 | 2,091 | 3,850 | 1,817 |

| Exhaust Gas Temperature (°F / ℃) | 875 | 468 | 1,000 | 538 |

| Heat Rejection to Ambien Air (BTU/min / kW) | 2,825 | 50 | 2,450 | 43 |

| Heat Rejection to Exhaust Gas (BTU/min / kW) | 29,500 | 519 | 25,700 | 452 |

| Heat Rejection to HTC Coolant (BTU/min / kW) | 9,900 | 174 | 10,200 | 179 |

| System Technical Data of CCEC QSK19-C700A Industrial Engine | ||

| Intake Air System | Maximum Air Temperature Rise Over Ambient at Turbocharger Compressor Inlet | 30 delta °F / 16.7 delta °C |

| Maximum Intake Air Restriction with-Clean Filter | 15 in-H2O / 3.7 kPa | |

| Maximum Intake Air Restriction with-Dirty Filter | 25 in-H2O / 6.2 kPa | |

| Minimum Air Cleaner Dirt Holding Capacity | 25 g / cfm | |

| Maximum Intake Air Bleed for Accessories at Intake Manifold (Not Including Air Compressor) | N/A | |

| Recommended Intake Piping Size (Inner Diameter) | 5.8 in / 147 mm | |

| Exhaust System | Maximum Static Bending Moment at Exhaust Outlet Flange | 20 lb-ft / 27 N.m |

| Recommended Exhaust Piping Size (Inner Diameter) | 8.00 in / 203 mm | |

| Maximum Exhaust Restriction | 3 in-Hg / 10 kPa | |

| Lubrication System | Nominal Operating Oil Pressure At – Minimum Low Idle Speed | 20 PSI / 138 kPa |

| Nominal Operating Oil Pressure At – Advertised Speed | 70 PSI / 483 kPa | |

| Minimum Oil Pressure Within 4 Seconds of Engine First Firing at Minimum Low Idle Speed (Measured at Turbocharger Oil Inlet) | 17 PSI / 117 kPa | |

| Maximum Oil Flow To All Accessories | 5 gpm / 18.93 L/min | |

| Maximum Oil Pressure Spike On Cold Engine | 150 PSI / 1034 kPa | |

| Fuel System | Maximum Heat Rejection to Return Fuel Which Occurs at The Following Conditions-Fuel Return Flow | 603 lb/hr / 274 kg/hr |

| Maximum Heat Rejection to Return Fuel Which Occurs at The Following Conditions-Fuel Return Temperature (Prior to Fuel Cooler) | 150 °F / 66 °C | |

| Maximum Heat Rejection to Return Fuel Which Occurs at The Following Conditions | 150 BTU/min / 3 kW | |

| Maximum Fuel Supply Flow | 864 lb/hr / 392 kg/hr | |

| Maximum Fuel Return Flow | 561 lb/hr / 254 kg/hr | |

| Maximum Fuel Supply Temperature (Measured at On-Engine Fuel Inlet Fitting) | 160 °F / 71 °C | |

| Maximum Fuel Supply Pressure (Measured at On-Engine Fuel Inlet Fitting) | N/A | |

| Maximum Fuel Return Restriction (Measured at On-Engine Fuel Drain Fitting) | 21 in-Hg / 71 kPa | |

| Fuel System-Stage 1 filter(s) | Maximum Combined Fuel Supply Restriction of Stage 1 Assembly & OEM Plumbing (Measured at On-Engine Fuel Inlet Fitting) With-Clean Stage 1 Fuel Filter(S) at Maximum Fuel Supply Flow | 5 in-Hg / 16.9 kPa |

| Maximum Combined Fuel Supply Restriction of Stage 1 Assembly & OEM Plumbing (Measured at On-Engine Fuel Inlet Fitting) With-Dirty Stage 1 Fuel Filter(S) at Maximum Fuel Supply Flow | 10 in-Hg / 34.0 kPa | |

| Nominal Restriction of Clean Stage 1 Fuel Filter Assembly at Maximum Fuel Supply Flow | 1 in-Hg / 4.0 kPa | |

| Maximum Fuel Inlet Pressure Measured at Stage 1 Inlet | 5 PSI / 34.0 kPa | |

| Recommended Maximum Fuel Inlet Pressure For Seeing Is Believing® (Measured at Stage 1 Inlet) | 1 PSI / 4.0 kPa | |

| Cranking System | Cooling System Type | 1 Pump-1 Loop |

| Minimum Fill Rate | 5 gpm 19 L / min | |

| Maximum Deaeration Time | 25 min | |

| Acceptable Types of Deaeration Systems | Fully Deaerating | |

| Minimum Water Pump Inlet Pressure With Fully Deaerating Cooling System | N/A | |

| Maximum Static Head of Coolant Above Crankshaft Centerline | 60 ft / 18.3 m | |

| Minimum Pressure Cap Rating at Sea Level | 7 PSI / 48 kPa | |

| Maximum Pressure Cap Rating at Sea Level | 15 PSI / 103 kPa | |

| Minimum Coolant Expansion Space (% of Total Cooling System Capacity) | 5% | |

| Minimum Drawdown (% of Total Cooling System Capacity) | 11% | |

| Minimum Cranking Speed | 150 RPM | |

| Maximum Parasitic Load 10 °F (-12 °C) | N/A | |

| Unaided Cold Start-Minimum Ambient Temperature | 10 °F / -12.2 °C | |

| Unaided Cold Start-Cranking Torque at Minimum Unaided Cold Start Temperature | 1302 lb-ft / 1765 N.m | |

| Aided Cold Start-Minimum Ambient Temperature with Only Ether | -5 °F /-21 °C | |

| Aided Cold Start -Minimum Ambient Temperature with Only Coolant And Oil Heaters | -5 °F /-21 °C | |

| Charge-Air Cooling (CAC) System | Maximum Intake Manifold Temperature at 77 °F (25 °C) Ambient Air Temperature | 120 °F / 49 °C |

| Maximum Pressure Drop Across Charge-Air Cooler And OEM CAC Piping (Impd) | 4 in-Hg / 13.5 kPa | |

| Maximum Intake Manifold Temperature Differential (Ambient to Imt) (Imtd) | 43 delta °F / 23.9 delta °C | |

| Electrical System | System Voltage | 24 V |

| Minimum Battery Capacity for Engine Only [Cold Soak at 0 °F (-18 °C) Or Above]-Cold Cranking Amperes (Cca) | 900 CCA | |

| Minimum Battery Capacity for Engine Only [Cold Soak at 0 °F (-18 °C) Or Above]-Reserve Capacity (Rc) | 320 min | |

| Scopes of Supply of CCEC QSK19-C700A Industrial Engine | |

| Fuel System | Fuel Transfer Pump |

| High-Pressure Fuel Pump | |

| Fuel Filter | |

| Exhaust System | Exhaust Manifold |

| Turbocharger | |

| Exhaust Elbow | |

| Air Intake System | Air Intake Manifold |

| Starting System | Starter Motor |

| Starter Rely | |

| Cooling System | Water Pump |

| Engine Fan | |

| Standard Radiator | |

| Power Output System | Flywheel |

| Standard Flywheel Housing | |

| Lubricating System | Oil Pump |

| Oil Filter | |

| Charging System | Charging Alternator |

| Engine Shut-Down System | Engine Fuel Shut-Off Solenoid |

| Engine Mounting System | Engine Mounting Bracket |

| Engine Auxiliary Accessories | Air Compressor |

| Optional Accessories of CCEC QSK19-C700A Industrial Engine | |

| Air Intake System | Air Intake Pre-Heater |

| Air Intake Shut-Off Valve | |

| Air Filter | |

| Air Intake Pre-Filter | |

| Air Filter Alarm System | |

| Exhaust System | Muffler & Bellows |

| Flame Trap | |

| Spark Arrestor Type Muffler & Bellows | |

| Dpf System | |

| Fuel System | Coarse Filter |

| Fuel Pre-Heater | |

| Lubricating System | Oil Pre-Heater |

| Starting System | Manual Magnetic Dc Contactor |

| Dual Ears Flywheel Housing | |

| Spring Starter Motor | |

| Air Starter Motor | |

| Hydraulic Starter Motor | |

| Manual Magnetic Dc Contactor | |

| Cooling System | Silent Type Radiator |

| Plateau Radiator | |

| Salt-Spray Resistant Radiator | |

| Coolant Pre-Heater | |

| Jacket Water Heater | |

| Engine Auxiliary Accessories | Hydraulic Oil Pump |

| Air Conditioner Compressor | |

| Control System | Option for Engine Monitoring System, Control System with Wiring Harness |

| Option for Self-Protection System that Integrated with Alarm System | |

| Power Output System | Clutch |

| Engine Mounting System | Shock Absorber Pad |

| Modifiable Components of CCEC QSK19-C700A Industrial Engine | |

| Air Intake System | Installation Position of Air Filter |

| Upgrade to Heavy-Duty Type Air Filter | |

| Charging System | 12V Charging Alternator for 12v Electric System |

| Explosion-Proof Charging Alternator | |

| Upgrading to Specified Brand and Specifications of Charging Alternator | |

| Exhaust System | Water-Cooled Exhaust Manifold |

| Water-Cooled Turbocharger | |

| Modify Option for Installation Position and Direction of Turbocharger | |

| Lubricating System | Oil Pan Position |

| Number of Dipstick | |

| Position of Dipstick Can Choose from 6 Positions | |

| Modify Option for Oil Filter to be Remote Installation | |

| Engine Shut-Down System | 12V Solenoid for 12V Electric System |

| Explosion-Proof Solenoid | |

| Starting System | Upgrading to Specified Brand and Specifications of Starter Motor |

| 12V Starter Motor for 12V Electric System | |

| Fuel System | Upgrade to Fuel Filter that Integrated with Fuel Transfer Pump and Fuel Pre-Heater |

| Engine Auxiliary Accessories | All of Auxiliary System can Choose Specified Brands and Specifications |

| Additional Auxiliary Systems Can be Added for Special Applications | |

| Cooling System | Modify Option for Engine Fan Into Blower Fan or Suction Fan |

| Modify Option Central Position of Engine Cooling Fan | |

| Option for Type of Engine Fan From Mechanical Type or Electric | |

| Power Output System | Modify Option for Size of Flywheel Housing and Flywheel |

| Dual-Ear Flywheel Housing (For Twin-Starter System) | |

| Some of Models can Modify Flywheel Housing Into PTO Integrated Type | |

| Engine Have Connecting Port of PTOs, That Able to Provide Power Output | |

| Engine Mounting System | Modify Option for Engine Mounting Bracket |

***Note: All Above Data are Just for Reference, All Data Might Change Without Notices or Updates, Please Contact Our Sales Team to Confirm All Details Via WhatsApp or Email.